- Home

- Products

- Stainless Steel Worm Gear Clamp

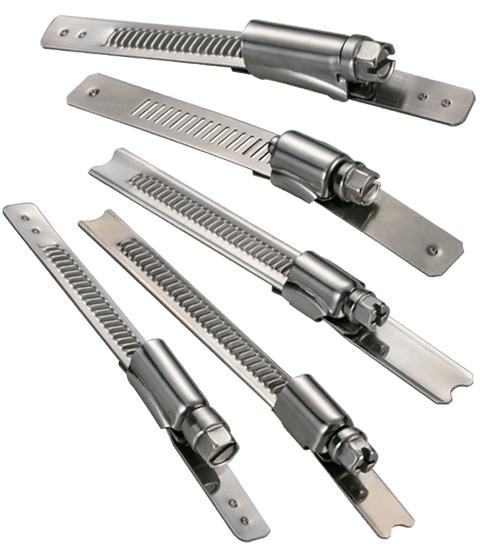

- STRETCHED TYPE CHIMNEY PIPE CLAMP CONNECTOR

STRETCHED TYPE CHIMNEY PIPE CLAMP CONNECTOR

Product Description

- Band width: available in 9mm, 12mm, and 12.7mm

- 0.6mm band thickness for 9mm & 12.7mm band

- 0.7mm band thickness for 12mm band

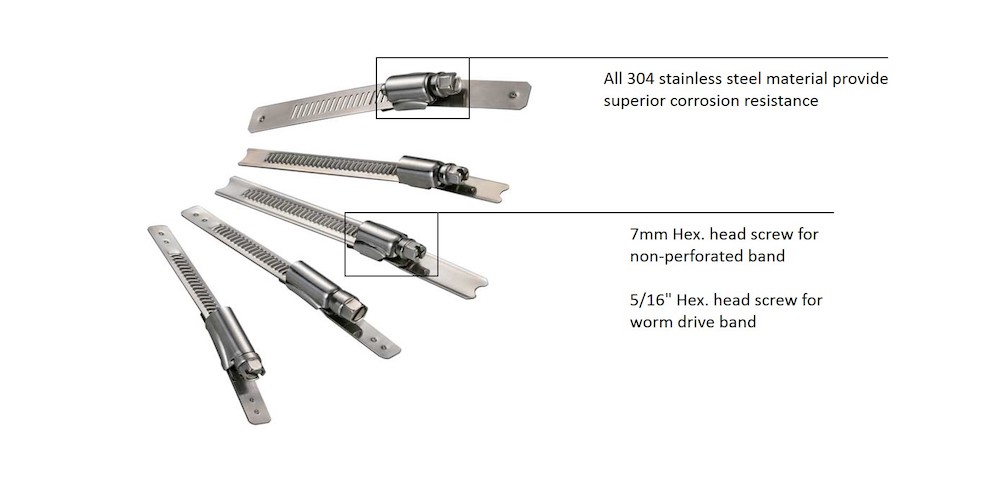

- All 304 stainless steel material is superior corrosion resistance

- 7mm Hex. head screw for non-perforated band

- 7.9mm (5/16") Hex. head screw for worm drive band

- Under RoHS & REACH standard

- Stretched type worm gear hose clamps

- Stretched clamps type

- Straight bar clamps type

- Strip clamps type

Feature

Material

Band, housing and screw all parts are made of 304 stainless steel.

Tightening Torque

The recommended installation torque is 4.0 Nm (35 in-lbs).

Application

Chimney, Construction

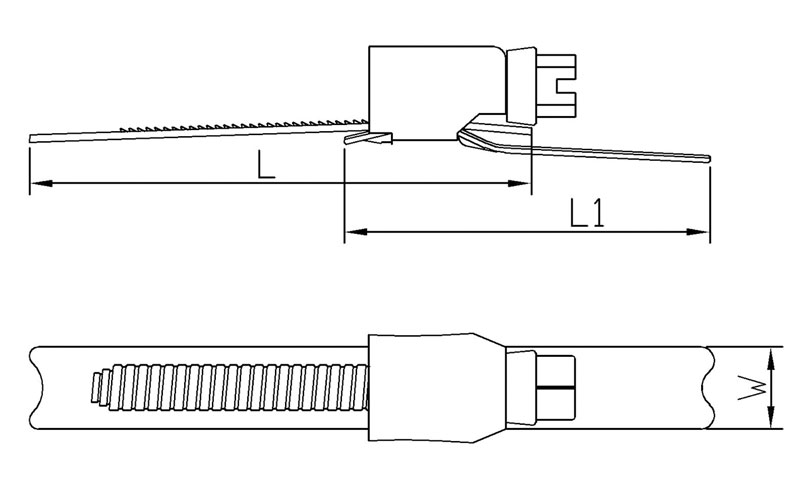

| Chimney Pipe Connector Description | ||||

|---|---|---|---|---|

| W | L | L1 | Length For Gear | Part Number |

| 9 mm | 65 mm | 40 mm | 48 mm | 14040-09065 |

| 9 mm | 90 mm | 40 mm | 74 mm | 14040-09090 |

| 9 mm | 140 mm | 40 mm | 122 mm | 14040-09140 |

| 12 mm | 90 mm | 55 mm | 74 mm | 14040-12090 |

| 12 mm | 115 mm | 55 mm | 98 mm | 14040-12115 |

Packaging

YDS chimney pipe connectors are packed in bulk package.

- * NO logo and brand on our regular boxes

- * We can provide customer barcode and private label for blister card packaging

- * Customer designed packaging are available on request

Bulk packaging: 100 clamps per box for all sizes, then shipped in cartons.

Accessories

We are also provide the flexible shaft nut driver (PN: 80011-07) for helping your work easily.

- * The flexible shaft provide 90° curved work in hard to reach places

- * The nut driver is easier to work then the plus/minus screwdrivers