- Home

- Products

- Stainless Steel Worm Gear Clamp

- Advanced Embossed Worm Gear Hose Clamps

Advanced Embossed Worm Gear Hose Clamps

Product Description

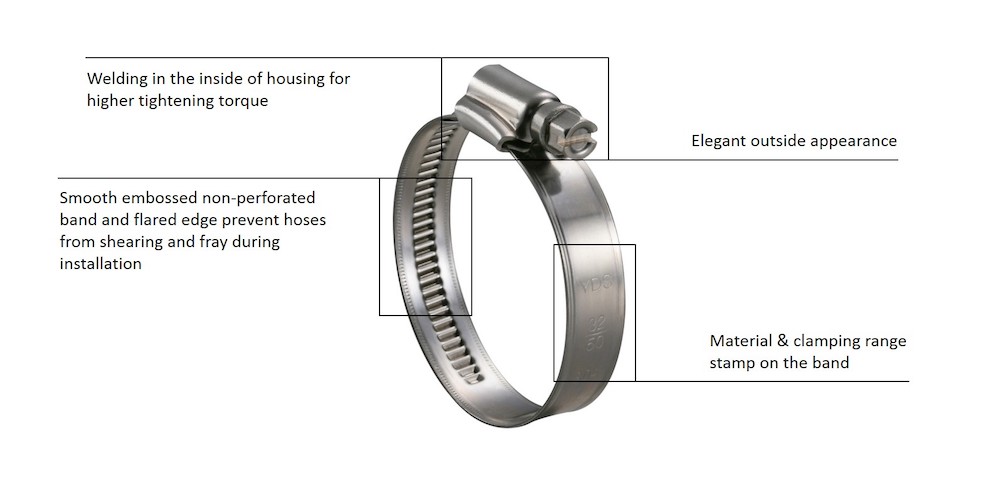

- Precision-engineered and elegant appearance.

- Welding in the inside of housing for higher tightening torque.

- In accordance with the DIN 3017 and RoHS & REACH standard.

- The smooth non-perforated band and flared edge band prevent hoses from cutting and fraying during installation.

- Band width: 9mm & 12mm are available.

- Hex. head screw: 7mm width for both band width hose clamps.

- Material and clamping range are stamped on the band.

- W4 and W5 stainless steel are superior corrosion resistance.

Feature

Material

| evereon Part No. | Material Type | BAND | HOUSING | SCREW | |

|---|---|---|---|---|---|

| 10220- series | W2 (430 S.S.) | AISI 430 Stainless Steel | AISI 430 Stainless Steel | Plated Carbon Steel |  |

| 10240- series | W4 (304 S.S.) | AISI 304 Stainless Steel | AISI 304 Stainless Steel | AISI 304 Stainless Steel |  |

| 10250- series | W5 (316 S.S.) | AISI 316 Stainless Steel | AISI 316 Stainless Steel | AISI 316 Stainless Steel |  |

Tightening Torque

9mm band width hose clamps: The recommended installation torque is 4.0 Nm (35 in-lbs).

12mm band width hose clamps: The recommended installation torque is 5.0 Nm (44 in-lbs)

Application

Industrial Hardware, Industrial Machinery, Agriculture, Automotive, Water Plumbing, Marine, HVAC, Gas

| Clamping Range (Size, Diameter) | Part Number | ||||||

|---|---|---|---|---|---|---|---|

| Band Width | Min. (mm) | Max. (mm) | Min. (inch) | Max. (inch) | W2 (430 S.S.) | W4 (304 S.S.) | W5 (316 S.S.) |

| 9 mm | 8 | 12 | 5/16 | 1/2 | 10220-09012 | 10240-09012 | 10250-09012 |

| 10 | 16 | 3/8 | 5/8 | 10220-09016 | 10240-09016 | 10250-09016 | |

| 12 | 20 | 1/2 | 3/4 | 10220-09020 | 10240-09020 | 10250-09020 | |

| 12 | 22 | 1/2 | 7/8 | 10220-09022 | 10240-09022 | 10250-09022 | |

| 16 | 25 | 5/8 | 1 | 10220-09025 | 10240-09025 | 10250-09025 | |

| 16 | 27 | 5/8 | 1-1/16 | 10220-09027 | 10240-09027 | 10250-09027 | |

| 20 | 32 | 3/4 | 1-1/4 | 10220-09032 | 10240-09032 | 10250-09032 | |

| 25 | 40 | 1 | 1-5/8 | 10220-09040 | 10240-09040 | 10250-09040 | |

| 30 | 45 | 1-3/16 | 1-3/4 | 10220-09045 | 10240-09045 | 10250-09045 | |

| 32 | 50 | 1-1/4 | 2 | 10220-09050 | 10240-09050 | 10250-09050 | |

| 40 | 60 | 1-5/8 | 2-3/8 | 10220-09060 | 10240-09060 | 10250-09060 | |

| 50 | 70 | 2 | 2-3/4 | 10220-09070 | 10240-09070 | 10250-09070 | |

| 60 | 80 | 2-3/8 | 3-1/8 | 10220-09080 | 10240-09080 | 10250-09080 | |

| 70 | 90 | 2-3/4 | 3-1/2 | 10220-09090 | 10240-09090 | 10250-09090 | |

| 80 | 100 | 3-1/8 | 4 | 10220-09100 | 10240-09100 | 10250-09100 | |

| 90 | 110 | 3-1/2 | 4-3/8 | 10220-09110 | 10240-09110 | 10250-09110 | |

| 100 | 120 | 4 | 4-3/4 | 10220-09120 | 10240-09120 | 10250-09120 | |

| Clamping Range (Size, Diameter) | Part Number | ||||||

|---|---|---|---|---|---|---|---|

| Band Width | Min. (mm) | Max. (mm) | Min. (inch) | Max. (inch) | W2 (430 S.S.) | W4 (304 S.S.) | W5 (316 S.S.) |

| 12 mm | 16 | 25 | 5/8 | 1 | 10220-12025 | 10240-12025 | 10250-12025 |

| 16 | 27 | 5/8 | 1-1/16 | 10220-12027 | 10240-12027 | 10250-12027 | |

| 20 | 32 | 3/4 | 1-1/4 | 10220-12032 | 10240-12032 | 10250-12032 | |

| 25 | 40 | 1 | 1-5/8 | 10220-12040 | 10240-12040 | 10250-12040 | |

| 30 | 45 | 1-3/16 | 1-3/4 | 10220-12045 | 10240-12045 | 10250-12045 | |

| 32 | 50 | 1-1/4 | 2 | 10220-12050 | 10240-12050 | 10250-12050 | |

| 40 | 60 | 1-5/8 | 2-3/8 | 10220-12060 | 10240-12060 | 10250-12060 | |

| 50 | 70 | 2 | 2-3/4 | 10220-12070 | 10240-12070 | 10250-12070 | |

| 60 | 80 | 2-3/8 | 3-1/8 | 10220-12080 | 10240-12080 | 10250-12080 | |

| 70 | 90 | 2-3/4 | 3-1/2 | 10220-12090 | 10240-12090 | 10250-12090 | |

| 80 | 100 | 3-1/8 | 4 | 10220-12100 | 10240-12100 | 10250-12100 | |

| 90 | 110 | 3-1/2 | 4-3/8 | 10220-12110 | 10240-12110 | 10250-12110 | |

| 100 | 120 | 4 | 4-3/4 | 10220-12120 | 10240-12120 | 10250-12120 | |

| 110 | 130 | 4-3/8 | 5-1/8 | 10220-12130 | 10240-12130 | 10250-12130 | |

| 120 | 140 | 4-3/4 | 5-1/2 | 10220-12140 | 10240-12140 | 10250-12140 | |

| 130 | 150 | 5-1/8 | 5-7/8 | 10220-12150 | 10240-12150 | 10250-12150 | |

| 140 | 160 | 5-1/2 | 6-1/4 | 10220-12160 | 10240-12160 | 10250-12160 | |

| 150 | 170 | 5-7/8 | 6-3/4 | 10220-12170 | 10240-12170 | 10250-12170 | |

| 160 | 180 | 6-1/4 | 7 | 10220-12180 | 10240-12180 | 10250-12180 | |

| 170 | 190 | 6-3/4 | 7-1/2 | 10220-12190 | 10240-12190 | 10250-12190 | |

| 180 | 200 | 7 | 7-7/8 | 10220-12200 | 10240-12200 | 10250-12200 | |

| 190 | 210 | 7-1/2 | 8-1/4 | 10220-12210 | 10240-12210 | 10250-12210 | |

| 200 | 220 | 7-7/8 | 8-5/8 | 10220-12220 | 10240-12220 | 10250-12220 | |

| 210 | 230 | 8-1/4 | 9 | 10220-12230 | 10240-12230 | 10250-12230 | |

| 220 | 240 | 8-5/8 | 9-3/8 | 10220-12240 | 10240-12240 | 10250-12240 | |

| 230 | 250 | 9 | 9-7/8 | 10220-12250 | 10240-12250 | 10250-12250 | |

| 240 | 260 | 9-3/8 | 10-1/4 | 10220-12260 | 10240-12260 | 10250-12260 | |

| 290 | 310 | 11-1/2 | 12-1/4 | 10220-12310 | 10240-12310 | 10250-12310 | |

| 340 | 360 | 13-3/8 | 14-1/8 | 10220-12360 | 10240-12360 | 10250-12360 | |

| 390 | 410 | 15-3/8 | 16-1/8 | 10220-12410 | 10240-12410 | 10250-12410 | |

| 440 | 460 | 17-3/8 | 18-1/8 | 10220-12460 | 10240-12460 | 10250-12460 | |

| 490 | 510 | 19-1/4 | 20 | 10220-12510 | 10240-12510 | 10250-12510 | |

Packaging

YDS advanced embossed worm gear hose clamps are available in bulk packaging, pack of 10, blister card packaging, polybag packaging, tag packaging, and customer designed packaging.

- * NO logo and brand on our regular boxes

- * We can provide customer barcode and private label for blister card packaging

- * Customer designed packaging are available on request

Bulk packaging: 100 clamps per box for small sizes, 50 clamps per box for large sizes, then shipped in cartons.

Pack of 10: 10 clamps per box, then shipped in cartons.

Blister card packaging: each set blister card packaging with 2 or 4 clamps.

Polybag packaging: each set polybags packaging are available in 2, 5, 10 clamps, or customer packaging.

Tag packaging: each clamp is packed with 1 private label.

Accessories

We are also provide the flexible shaft nut driver (PN: 80011-07) for helping your work easily.

- * The flexible shaft provide 90° curved work in hard to reach places

- * The nut driver is easier to work then the plus/minus screwdrivers